Meat cutter machines have been available in the market for years. In fact, there have been great innovations when it comes to these machines. However, the number of these machines has been increasing to the point where it becomes more difficult to select the right one. Nowadays, the clients have become smarter. Thus, they choose the multifunctional meat cutter machine.

The standard cutter of this one is 3mm thick. However, one could select from 2.5-30mm thick. This only means that with the multifunctional meat cutter machine, one could change the thickness of the cutter depending on where they are going to use it. It could be used to shred, dice and slice the meat. It is truly multifunctional for it could do almost everything that could be done to meat. What is great about this machine is that it ensures security.

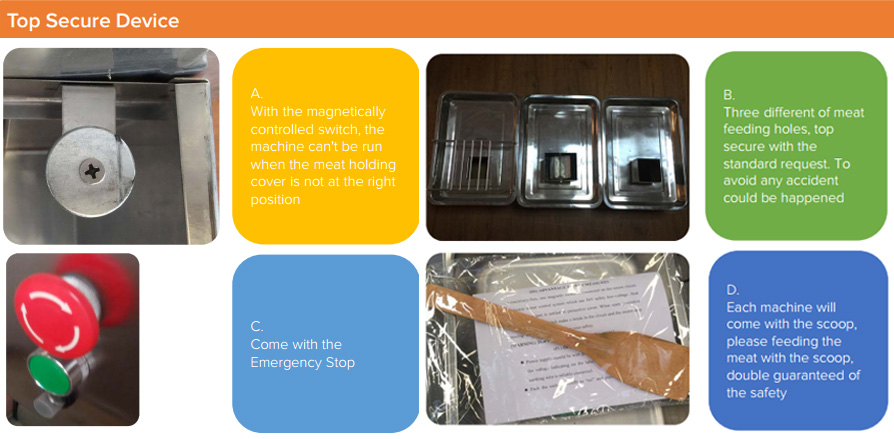

First, it has a magnetically controlled switch. With it, the machine would not run when the holding cover for the meat is not in at the right position. Second, it has 3 feeding holes for the meat in order to avoid any accident from happening. Third, in case an unavoidable thing happens, there is always the emergency stop that the user could rely on in case of an emergency.

Aside from providing top security, the multifunctional meat cutter machine also assures top quality as well as stability. First, it has a stainless steel body, which is very ideal for a meat cutter. Moreover, the manufacturer of the machine is also the one that manufactures the blades in this machine. Thus, they are able to control the quality of the entire machine as well as its other parts. Third, aside from the body being stainless steel, the blade holders and the blade itself was also made from stainless steel. Moreover, the manufacturers also ensures that it has meets the food grade standards. Last but not the least, the clients can be rest assured that the entire assembling process are monitored to ensure the production of the highest quality meat cutter possible.

The multifunctional meat cutter machine is very easy to maintain and clean. The user does not need to clean the blade group. They only need to put it into the fridge with the temperature that is below 6°. Moreover, in case the client wanted to clean it, they do not need to take it down. They could freely wash it as the body of the machine is well sealed. There is also no need to worry when it comes to the rubber sealer since it is also water proof.

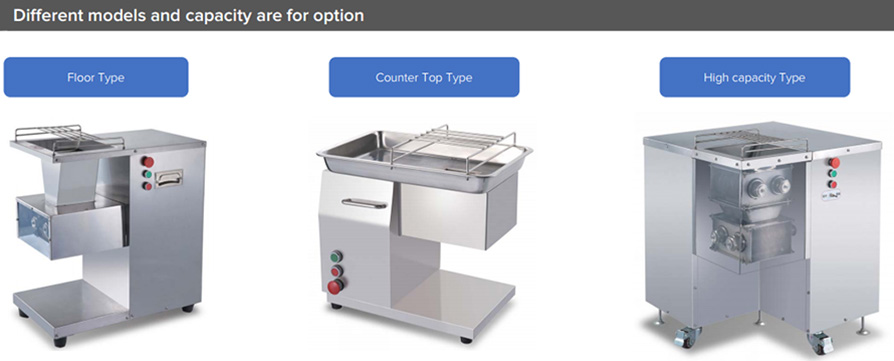

Nowadays, the client could even select the blade group of their choice since the manufacturer provides them tons of options to choose from. Moreover, the feeding holes for the meat are also popular in different markets including the European, American and the Domestic market. One could even select different models as well as the capacity of the machine that they are looking for. The multifunctional meat cutter machine is definitely one of the machines out there that has a lot of potential in making the lives of the people easier and more convenient.

Comments